Burner Performance Tips for Ultimate Safety and Efficiency

In today's world, understanding Burner Performance Tips is essential for ensuring both safety and efficiency in various heating processes. Whether you are operating a residential furnace or an industrial boiler, the performance of your burner directly impacts fuel consumption, emissions, and overall system reliability. To achieve optimal burner performance, a combination of regular maintenance, proper adjustments, and the right operating conditions are crucial.

Burners can refer to several different things, but most commonly it refers to small, portable stoves that are used for outdoor cooking and camping. These stoves typically use propane or butane as fuel and can be used to boil water, cook food, or provide heat in a variety of outdoor settings.

In addition to camping, burners are also commonly used for outdoor events like barbecues, picnics, and tailgating. They come in a variety of sizes and styles, from compact single-burner stoves to larger multi-burner models. Some even come with grills or griddles for cooking food directly on the surface.

Burners can also refer to individuals who attend the annual Burning Man festival, which takes place in the Black Rock Desert of Nevada. These participants are known as "Burners" and are known for their creative, communal, and participatory spirit. The festival is centered around the burning of a large wooden effigy, and attendees often create elaborate art installations, costumes, and performances to share with others.

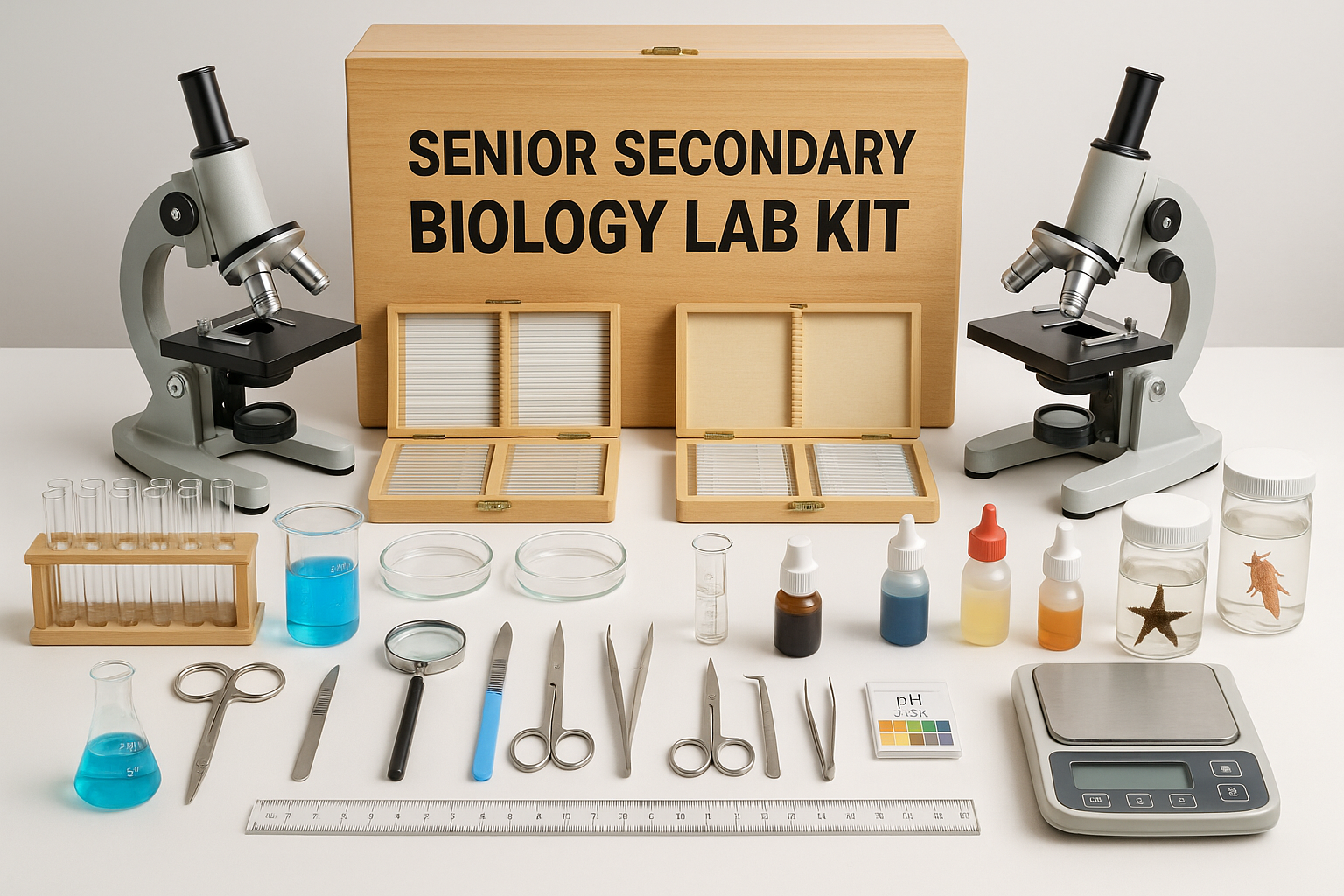

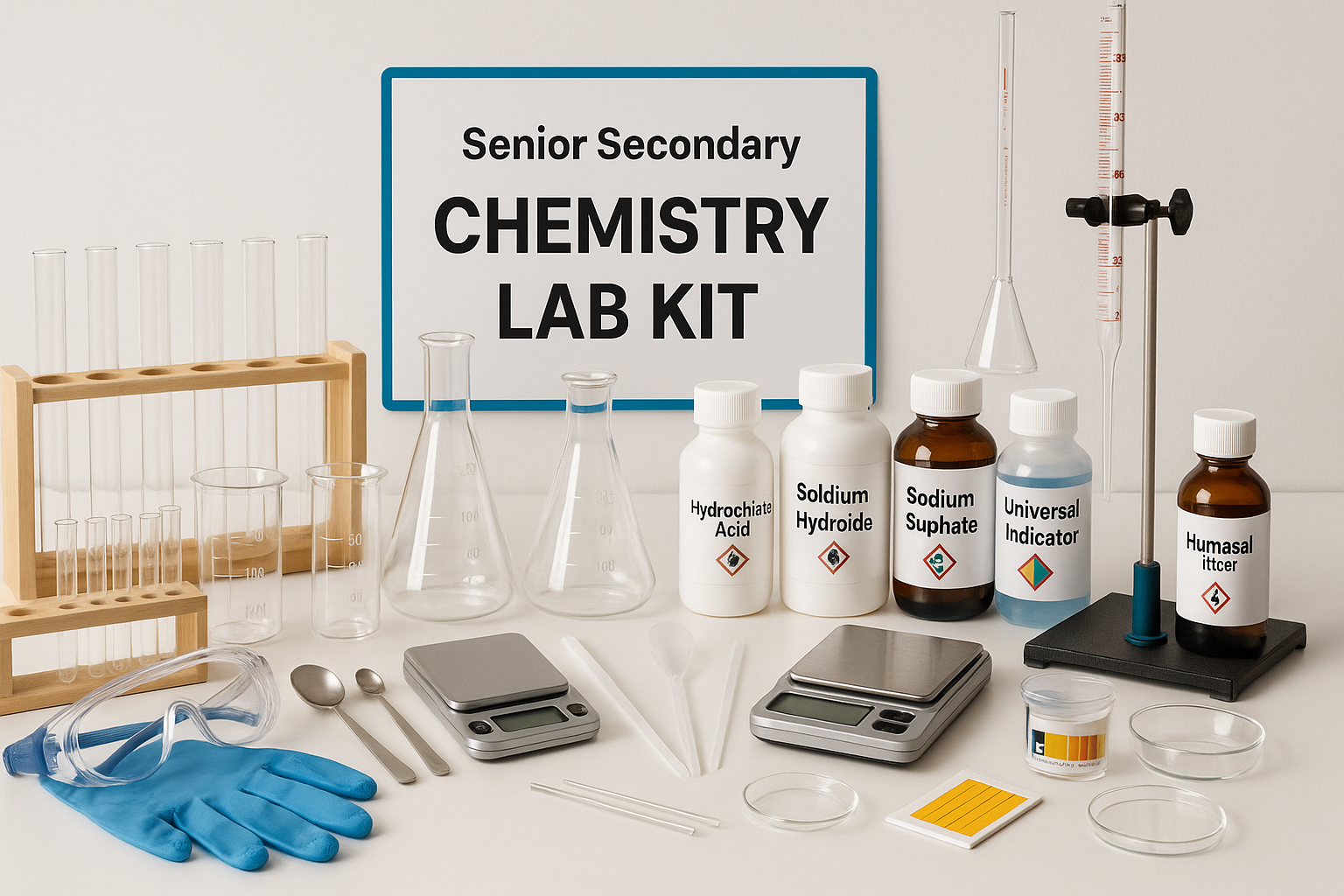

LABORATORYDEAL India maintains a good quality assurance of all its products and provides lab equipment at affordable and eco-friendly rates. The company provides lab equipment throughout and outside the country and has a network of dealers and distributors in various states, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal

The first step in improving burner performance is regular maintenance. This includes cleaning the burner components, such as the flame sensor, nozzle, and air intake areas. Dust and debris can significantly hinder performance, leading to incomplete combustion, which increases fuel usage and harmful emissions. Regularly replacing worn-out parts will also play a vital role in maintaining an efficient burner system.

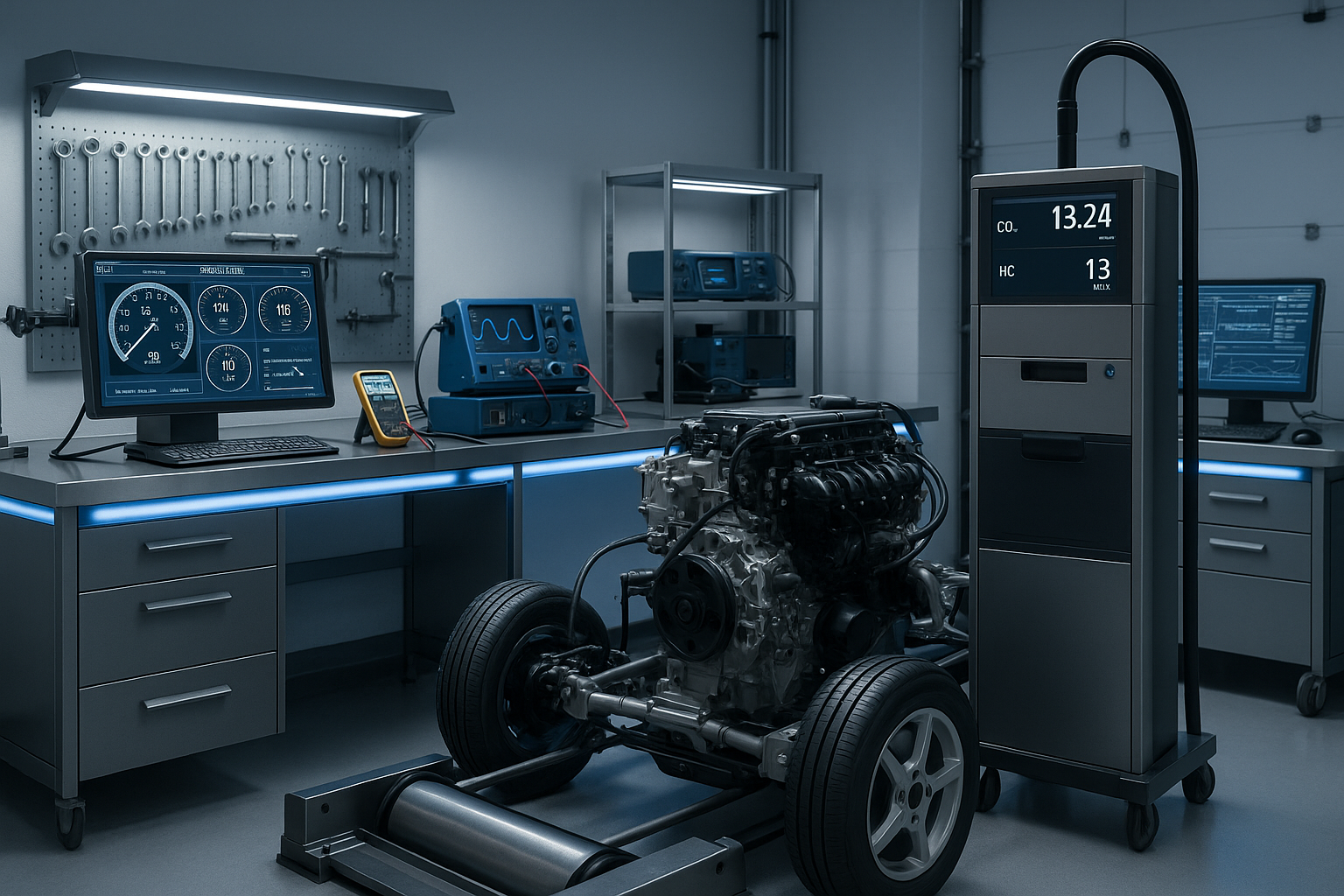

Another critical aspect is the calibration of airflow and fuel supply. Burners are designed to operate at specific air-to-fuel ratios. Ensuring that these ratios are maintained is essential for achieving the ideal combustion process. Using combustion analyzers to check the oxygen and carbon monoxide levels in the flue gas can provide valuable insights into burner performance. Proper tuning and adjustments can help in minimizing excess air and fuel usage.

Also, consider the type of fuel being used. Different fuels have distinct combustion properties, which can influence burner performance. Conducting tests when switching fuel types can help in fine-tuning the air-fuel mixture, ensuring the burner operates efficiently and safely. Additionally, using quality fuel that meets specifications can prevent issues such as clogging and corrosion within the burner system.

Furthermore, monitoring the operating temperature and pressure is vital for optimal performance. Maintaining the burner within the designed operating parameters will not only enhance efficiency but also prolong the lifespan of the equipment. Installing temperature and pressure gauges can provide real-time data allowing for immediate adjustments when necessary.

Finally, training personnel who operate and maintain the equipment is crucial. They should understand the principles of burner operation and the importance of safety protocols. Regular training sessions can emphasize the importance of adhering to regulations and safety measures, reducing the risk of accidents and improving overall efficiency.

Implementing these Burner Performance Tips enhances safety by minimizing risks and ensuring compliance with environmental regulations. Ultimately, a well-maintained and well-operated burner will lead to reduced fuel costs, lower emissions, and a safer working environment, underscoring the importance of these practices in any setting that relies on combustion technology.