Mining Engineering Equipment: Key Tools for Effective Operations

Mining engineering equipment plays a pivotal role in the success of any mining operation. Knowing the essential devices and tools is critical to optimize productivity and ensure operational safety. In this comprehensive guide, we will explore various types of equipment that are indispensable for mining engineering.

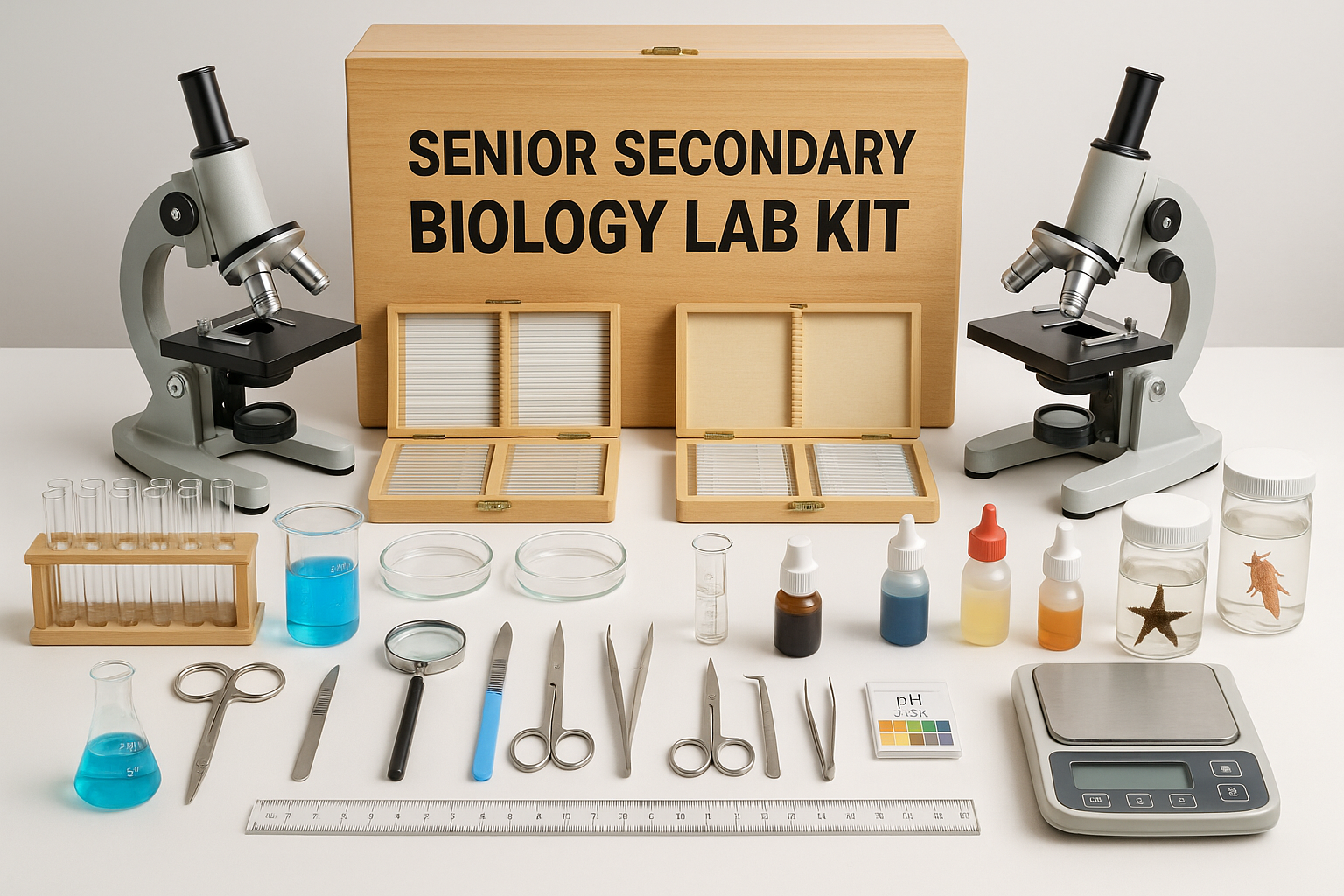

Mining engineering is a field that involves the extraction of valuable minerals and resources from the Earth's crust. Various types of lab equipment are used in mining engineering laboratories to conduct experiments, analyze samples, and perform research related to mining operations. Here are descriptions of some common mining engineering lab equipment:

-

Rock and Mineral Analysis Equipment: This equipment is used to examine the composition and characteristics of rocks and minerals. It includes tools such as X-ray diffractometers, X-ray fluorescence (XRF) analyzers, scanning electron microscopes (SEM), and optical microscopes. These instruments help determine the mineralogy, chemical composition, and physical properties of samples.

-

Sample Preparation Equipment: Sample preparation is an essential step in mining engineering labs. It involves crushing, grinding, and dividing large rock or mineral samples into smaller, representative portions for analysis. Equipment used for sample preparation includes jaw crushers, rotary crushers, pulverizers, and mills.

-

Flotation Machines: Flotation is a commonly used method in mineral processing to separate valuable minerals from gangue (unwanted material). Flotation machines create bubbles in a water-based slurry and selectively attach to specific minerals, allowing their separation. Different types of flotation machines are available, including mechanical and column flotation cells.

-

Magnetic Separators: Magnetic separators are used to separate magnetic minerals from non-magnetic materials. They utilize magnetic forces to attract and capture magnetic particles. Magnetic separators can be in the form of drum separators, magnetic pulleys, or high-intensity magnetic separators.

-

Gravity Separation Equipment: Gravity separation is a method used to separate minerals based on their specific gravity or density differences. Equipment like shaking tables, spiral concentrators, and centrifugal concentrators are used to separate minerals based on their density. These devices apply controlled water flow and mechanical vibrations to facilitate the separation process.

-

Sieves and Classifiers: Sieves and classifiers are used to classify and separate materials based on their particle size. In mining engineering labs, sieve analysis is conducted to determine the particle size distribution of crushed ores, minerals, and other granular materials. Various types of sieves and classifiers, including vibrating screens, rotary sieves, and hydrocyclones, are employed for this purpose.

-

Core Drilling Equipment: Core drilling is a technique used to extract cylindrical samples (cores) from underground or geological formations. Core samples provide valuable information about the structure, composition, and geotechnical properties of rocks. Core drilling equipment includes drilling rigs, core barrels, diamond drill bits, and core splitters.

-

Ventilation and Gas Monitoring Instruments: These instruments are used to measure and monitor air quality, gas concentrations, and airflow in mining environments. They include devices such as gas detectors, anemometers (for airflow measurement), and dust samplers. These instruments help ensure a safe and healthy working environment for miners.

These are just a few examples of the lab equipment used in mining engineering. The specific equipment utilized may vary depending on the nature of the research, the type of mining operation, and the focus of the laboratory.

LABORATORYDEAL India maintains a good quality assurance of all its products and provides lab equipment at affordable and eco-friendly rates. The company provides lab equipment throughout and outside the country and has a network of dealers and distributors in various states, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal

First and foremost, mining engineering equipment includes a variety of machinery used for the extraction of minerals from the earth. This equipment can be classified into several categories, including drilling, loading, transporting, and processing equipment. Each category serves a specific purpose and is designed to enhance the efficiency and effectiveness of mining operations.

Drilling Equipment

Drilling equipment is fundamental for conducting exploratory and extraction drilling. This category includes rotary drills, diamond core drills, and percussion drills. Rotary drills use a rotating bit to penetrate hard rock, while diamond core drills allow for the collection of core samples that can be analyzed for mineral content. Percussion drills, on the other hand, utilize a hammering action to break rock. With a range of drill sizes and capabilities, miners can tackle various geological formations.

Loading Equipment

Loading equipment is essential for transferring mined materials from the extraction site to transport vehicles. Common types of loading equipment include front-end loaders, excavators, and wheel loaders. These machines help in moving ore and waste material efficiently, reducing the time and labor involved in manual loading methods.

Transporting Equipment

Once materials are extracted and loaded, they require reliable transportation to processing facilities. Conveyors, trucks, and haulage systems make up this category of mining engineering equipment. Conveyor systems are particularly useful for moving materials over short to medium distances, while haul trucks transport large volumes of mined materials across longer distances. Transporting equipment must be durable and capable of handling harsh environments.

Processing Equipment

Processing equipment is crucial for transforming mined materials into valuable products. This phase involves crushing, grinding, and refining processes tailored to the specific minerals being extracted. Crushers and grinders reduce the size of rocks, while flotation cells and leaching tanks separate valuable minerals from waste materials. The selection of processing equipment directly influences the quality of the final product and the overall efficiency of the mining operation.

Safety Equipment

Safety should always be a priority in mining operations. Therefore, investing in appropriate safety equipment is critical. This includes personal protective equipment (PPE) such as helmets, gloves, and goggles, as well as tools like gas detectors and ventilation systems. Adequate safety measures not only protect workers but also help minimize accidents and ensure compliance with industry regulations.

Maintenance and Support Equipment

Maintenance equipment plays a significant role in ensuring that all other mining engineering equipment operates smoothly. This category includes tools for routine maintenance, such as torque wrenches, hydraulic jacks, and diagnostic tools. Regular maintenance helps prevent breakdowns and prolongs the lifespan of machinery, ultimately contributing to operational success.

Emerging Technologies in Mining Equipment

With the advent of technological advancements, the mining industry has seen the introduction of new equipment that enhances productivity and reduces environmental impact. Automation and remote-controlled machinery are becoming increasingly common. These innovations not only improve safety by reducing human presence in hazardous areas but also increase efficiency through precise operations.

Conclusion

In conclusion, understanding and utilizing the right mining engineering equipment is crucial for the success of any mining venture. From drilling and loading to transporting and processing materials, each type of equipment plays an integral role in optimizing the operation. By investing in modern technology and prioritizing safety, mining companies can enhance productivity, reduce environmental impact, and ensure the well-being of their workers.