Material Testing Equipment: Ensuring Accuracy and Reliability

Material Testing Equipment is crucial in assessing the properties and performance of various materials used in construction, manufacturing, and research. Accurate results derived from reliable testing equipment ensure that products meet safety standards and performance expectations, which is why choosing the right equipment is vital for any laboratory.

LABORATORYDEALExport is providing the world’s grandest products built by using excellent quality raw materials. Material Testing Lab Equipment is one of the fine instruments of Material Testing Lab Machines. These categories are supplying and exporting all around the world at high speed. We have made very strong connections all around in India and Abroad as well. We became a trustable producer and Material Testing Lab Equipment manufacturer. Material Testing System consists a wide range of equipment for supply, some of them are listed as follows: Vaccum Degassing Oven, Servo-Pneumatic Asphalt Testing System, Rolling Thin Film Oven, Resilient Modulus and Asphalt Testing System, Pressure Aging Vessel, Hamburg Wheel-Tracking Tester, Dynamic Loading System, Automatic Marshall Compactor with Rotating Base, Automatic Asphalt Content Tester, Tensile Strength Tester, Digital Impact Test Machine, Asphalt Coring Machine, Analog Tensile Testing Machine, Pendulum Impact Testing Machine, Impact Testing Machine (Izod & Charpy), Plate Load Test Apparatus and so many of the same kind of Material Testing Lab instruments. Nowadays, In Laboratory Equipment and Instruments, LABORATORYDEALExports sound much higher than others because of their standard quality products. If you are thinking about the purchasing of goods for practical usage, then you can easily find us. You just have to visit our website. For a detailed view of supplies with specifications, spool down the page and check for your requirement.

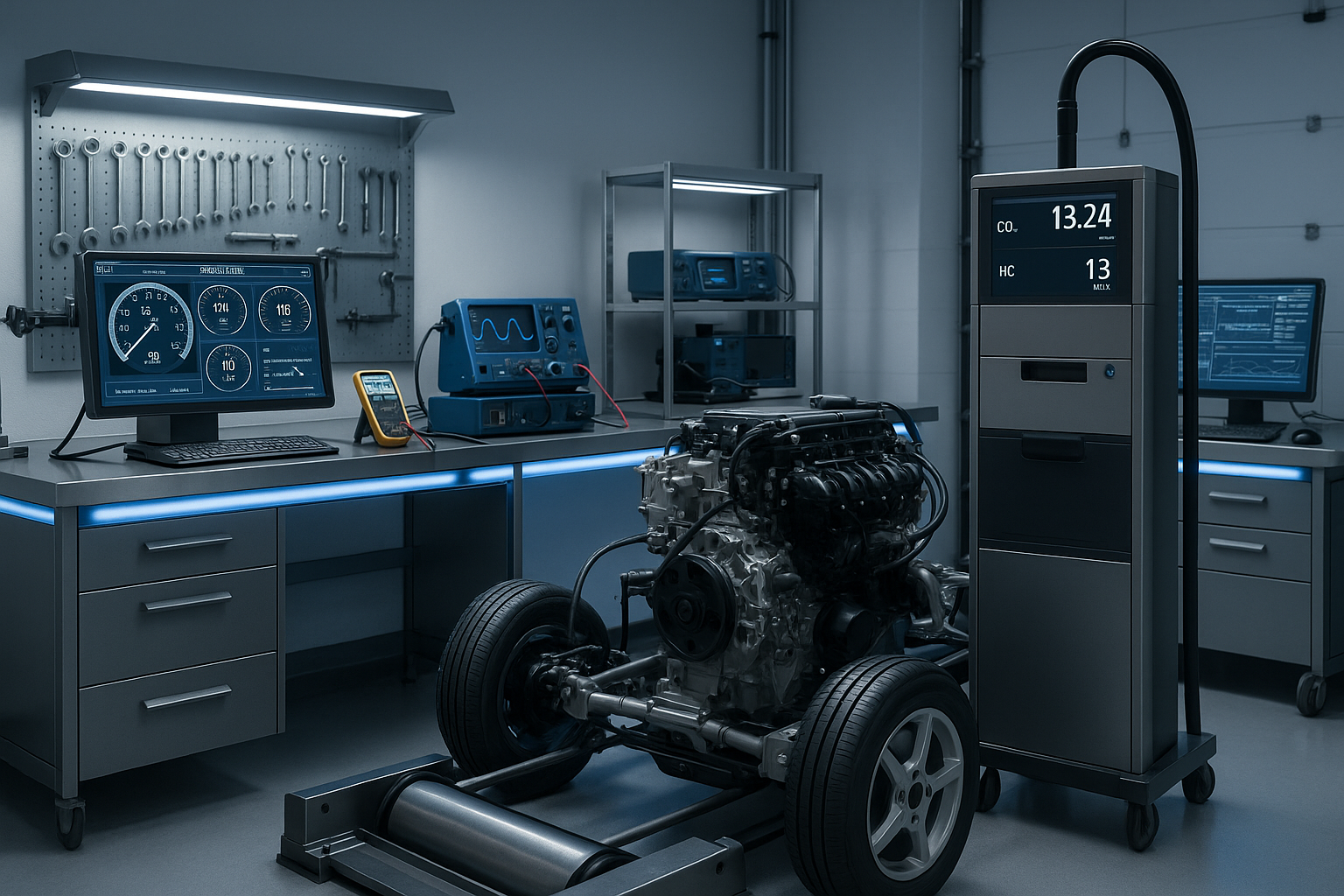

Material testing laboratory equipment is used for analyzing and evaluating various properties of materials such as mechanical strength, hardness, corrosion resistance, and thermal conductivity. The equipment can be broadly classified into the following categories:

-

Tensile Testing Machine: This equipment is used to determine the tensile strength, yield strength, elongation, and modulus of elasticity of metals, plastics, and other materials. The machine works by applying a tensile force to a test specimen until it fractures.

-

Compression Testing Machine: This equipment is used to determine the compressive strength of materials. The machine works by applying a compressive force to a test specimen until it fails.

-

Impact Testing Machine: This equipment is used to determine the impact resistance of materials. The machine works by striking a test specimen with a pendulum and measuring the amount of energy absorbed during the impact.

-

Hardness Testing Machine: This equipment is used to determine the hardness of materials. There are various methods of hardness testing such as Brinell, Rockwell, and Vickers, each requiring different types of machines.

-

Fatigue Testing Machine: This equipment is used to determine the endurance limit and fatigue life of materials subjected to cyclic loading. The machine works by applying repeated cycles of stress to a test specimen until it fails.

-

Corrosion Testing Equipment: This equipment is used to evaluate the corrosion resistance of materials in different environments. There are different types of corrosion tests such as salt spray, immersion, and electrochemical tests, each requiring specific equipment.

-

Thermal Conductivity Testing Equipment: This equipment is used to measure the thermal conductivity of materials. The machine works by applying a temperature difference across a test specimen and measuring the resulting heat flow.

These are just a few examples of the different types of material testing laboratory equipment available. The choice of equipment will depend on the specific properties of the material being tested and the requirements of the testing standards.

LABORATORYDEAL India maintains a good quality assurance of all its products and provides lab equipment at affordable and eco-friendly rates. The company provides lab equipment throughout and outside the country and has a network of dealers and distributors in various states, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal

In engineering and construction, material testing plays a fundamental role. Various tests are conducted to determine the strength, durability, and integrity of materials such as concrete, metal, plastics, and composites. These assessments are often critical in preventing failures and ensuring public safety. The incorporation of advanced technology in material testing equipment has led to more precise and efficient testing methods, thereby enhancing the reliability of results.

The types of material testing equipment vary widely, from simple tools to complex machines. Commonly used equipment includes tensile testers, hardness testers, compressive strength testers, impact testers, and fatigue testers. Each piece of equipment serves a unique purpose, allowing engineers and researchers to determine material characteristics under different conditions and loads.

Tensile testing machines are instrumental in evaluating the tensile strength of materials. These machines apply controlled tension to a material sample until it fails, providing critical data on the material's elasticity and yield point. Hardness testers assess the resistance of a material to deformation, with various methods available including Brinell, Rockwell, and Vickers tests, each suited for different types of materials.

Compressive strength testers evaluate how materials perform under compression, providing vital information for designing structures that can withstand weight and pressure. Impact testers measure the toughness of materials by assessing their ability to absorb energy during a sudden force, crucial for materials used in safety-critical applications.

Fatigue testers help in understanding how materials behave under cyclic loading and the number of cycles they can withstand before failure. This is essential for applications in industries like aerospace and automotive, where materials are subjected to repeated stress over time.

To achieve accurate results, it's essential for laboratories to maintain their material testing equipment properly. Regular calibrations and maintenance checks are necessary to ensure that the equipment functions correctly and provides reliable data. Laboratories should also implement standard operating procedures to minimize variability in test results and ensure consistency across different tests and samples.

Furthermore, the selection of appropriate testing standards is crucial. Various national and international standards govern material testing methods, such as ASTM, ISO, and EN standards. Laboratories must adhere to these guidelines to ensure the reliability and credibility of their testing results.

With the increasing emphasis on sustainability and environmental impact, material testing equipment also plays a significant role in evaluating the recyclability and environmental safety of materials. Modern equipment can assess the life cycle of materials, helping industries transition towards more sustainable practices.

In conclusion, investing in high-quality material testing equipment is a necessity for any lab aiming to produce accurate and reliable results. As technology continues to evolve, staying updated with the latest advancements in material testing will empower laboratories to meet the growing demands of industries and ensure safety and efficacy in product performance.

By understanding the capabilities and functions of material testing equipment, professionals can make informed decisions that will impact their projects and ultimately contribute to the advancement of materials science and engineering.