Laboratory Milk Testing Equipment

Laboratory milk testing equipment is essential for ensuring the quality and safety of milk products. In the dairy industry, maintaining high standards of milk quality is crucial for consumer health and regulatory compliance. The use of advanced laboratory milk testing equipment allows for accurate measurement of various parameters, including fat content, protein levels, and microbial contamination.

These equipment types are designed for a variety of tests that assess the physical and chemical properties of milk, enabling dairy producers to meet the standards set by health authorities. Some of the most common laboratory milk testing equipment includes milk refractometers, lactometers, dairy milk analyzers, and microbial testing kits. Each of these tools serves a specific purpose, providing detailed insights into the quality of milk and milk products.

Milk refractometers are used to measure the refractive index of milk, which correlates with its total solids content. This is a quick and efficient method for determining the concentration of solids in milk, helping producers adjust their processes accordingly. Similarly, lactometers provide a simple way to gauge the purity of milk, primarily by measuring its density. A lactometer reading can indicate whether water has been added to the milk—a common adulteration issue.

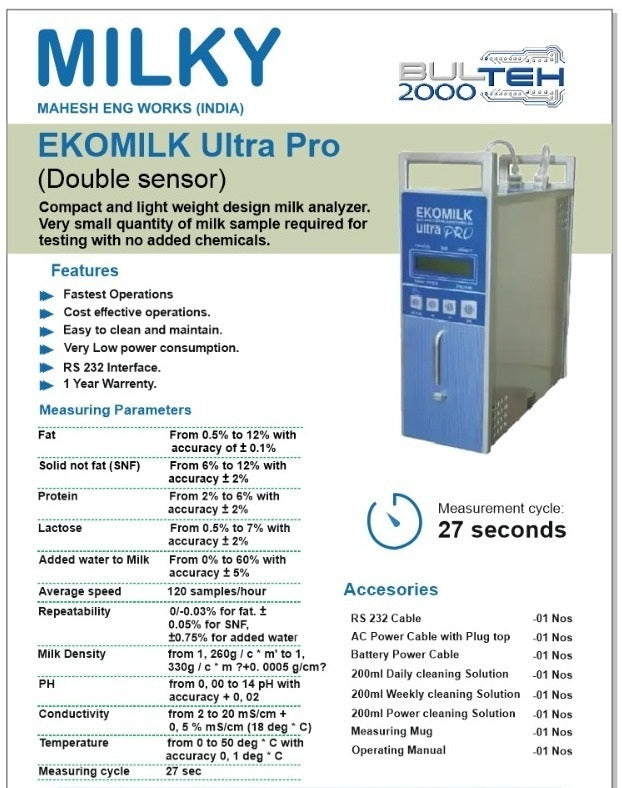

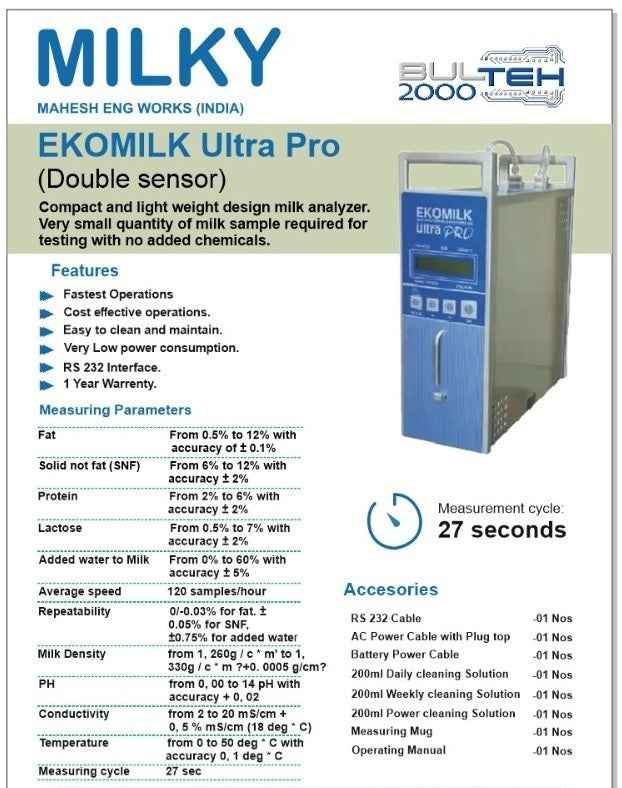

For more comprehensive analysis, dairy milk analyzers integrate multiple testing functionalities, allowing users to analyze fat, protein, lactose, and other components in one measurement. These devices often employ infrared technology or other analytical methods to ensure precision and reliability, which is vital for quality control in milk processing.

In addition to physical and chemical analysis, microbial testing is equally important. Laboratory milk testing equipment for microbial analysis includes culture media, incubators, and petri dishes that help detect pathogens or spoilage organisms. Such testing is critical to ensuring that milk products are free from harmful bacteria that can compromise consumer safety. Rapid detection kits are also available, providing quicker results and facilitating faster decision-making in production settings.

The use of automated systems in laboratory milk testing is an ongoing trend, allowing for efficiency and increased throughput. Automated analyzers can handle multiple samples independently, reducing the risk of human error and speeding up the testing process. Integration of laboratory information management systems (LIMS) with testing equipment further streamlines operations, making it easier to track results and manage data.

Laboratory milk testing equipment is not only beneficial for large dairy operations but also for smaller producers who wish to maintain high-quality standards. By investing in appropriate equipment, dairy farmers can enhance their product quality, gain consumer trust, and improve their market competitiveness.

Regular testing using laboratory milk testing equipment helps identify issues before they escalate into larger problems. By monitoring the quality parameters diligently, dairy producers can ensure that they are producing a safe and high-quality product. This is vital for maintaining compliance with industry regulations and standards, as well as earning consumer loyalty.

In conclusion, laboratory milk testing equipment plays a critical role in the dairy industry. It provides the necessary tools for quality assurance, regulatory compliance, and ultimately contributes to consumer health and satisfaction. As technology advances, these testing methodologies will continue to become more efficient and effective, further enhancing milk quality and safety in the industry.

Filter

Sort by