Categories

- 10 Best Bod Incubator 2025 at Lowest Price

- 10 Best Compound Microscopes 2025 at Lowest Prices

- 10 Best Lab Chemicals 2025 at Lowest Prices

- 10 Best Lab Equipment Suppliers 2025 - Lowest Prices Available

- 10 Best Lab Microscopes 2025

- 10 Best Microbiology Lab Equipment 2025 at Lowest Prices

- 10 Best Refrigerator Mortuary Freezer India

- 10 Best Student Microscopes 2025 at Lowest Prices

- 10 Best Vertical Autoclaves 2025 - Vertical Autoclaves Best Prices 2025

- Accessories Collection: Trendy and Essential Items

- Aerospace Engineering Equipment Collection for Optimal Research and Innovation

- Agriculture Lab Equipment for Precision Farming and Research

- Agriculture Lab Equipment Suppliers for Agriculture College Needs

- Agronomy Lab Equipment for Precise Agricultural Research

- analytical lab equipment for precision testing and research

- Anatomy Lab Equipment Collection for Education and Research

- Animal House Lab Equipment: Essential Tools for Research

- AUTOMOBILE LAB: Explore Innovations in Automotive Engineering

- ayurvedic drug testing laboratory for quality assurance and effectiveness

- Ayurvedic Lab Equipment Suppliers and Manufacturers for Colleges

- Ayurvedic Pharmacy Instruments: Essential Ayurvedic Pharmacy Tools

- B Pharmacy Equipment Suppliers: Quality Supplies for Your Pharmacy

- B. D. Instrumentation India: Leading Solutions in Instrumentation

- Best Microscope for Students in India: Top Picks for Students

- Binocular Microscope Collection

- Biochemistry lab equipment

- Biological Lab Equipment Collection

- Biological Lab Equipment for Research and Experimentation in Biological Sciences

- Biology Lab Equipment

- Biomedical Engineering Lab Equipment

- Biophysics Lab Equipment for Research and Experiments - Essential Tools for Biophysics Studies

- Biostatistics Lab Equipment

- Biotechnology Collection: Innovative Advances in Biotechnology

- Biotechnology Lab Tools and Equipment for Advanced Research

- Biotechnology Lab Tools for Efficient Research and Innovation

- Borolab Scientific Glass Pvt. Ltd.

- Botany Lab Supplies for All Your Plant Research Needs

- Botany Permanent Micro-Prepared Slides Collection - Botany Micro-Prepared Slides

- CAD Lab Collection - Innovative Designs and Solutions

- Cardiology Lab Equipment

- Central Drug House Collection - CDH

- CENTRAL WORKSHOP Collection: Premium Tools and Equipment for Every Project

- Centre for Community Medicine Lab Equipment Collection

- Centrifuge Machine Collection: Explore Top Models and Features

- Centrifuge Machine Suppliers India - Quality and Reliability at Its Best

- Chemical Engineering Equipment Collection

- Chemistry equipment

- Chemistry Lab Apparatus - Essential Chemistry Lab Equipment

- Chromatography Apparatus Collection for Efficient Separation Techniques

- Civil Engineering Collection: Essential Resources and Insights

- Clean Air Equipment

- College of Nursing Lab Equipment

- D Pharmacy equipment

- Dairy Analysis Instruments: Essential Tools in the Dairy Lab Collection

- Dental Autoclave Cost and Price Analysis Collection

- Dental Equipment Supply and Tools for Professionals

- Department of Anatomy Lab Equipment – Essential Anatomy Lab Equipment for Students and Professionals

- DEPARTMENT OF P'CEUTICAL CHEMISTRY Equipment - Pharmaceutical Chemistry Equipment

- DEPARTMENT OF P'CEUTICS Equipment - Pharmaceutical Equipment Collection

- DEPARTMENT OF PHARMACOGNOSY Equipment - Essential Tools for Research and Analysis

- DEPARTMENT OF PHARMACOLOGY Equipment

- Diffusion Cell Apparatus: Understanding Its Applications and Benefits

- Digital Centrifuge Machine Collection

- Distillation Equipment: Essential Distillation Apparatus for Your Collection

- Do Meter Collection: Unique Designs and Innovative Styles

- DYNAMICS OF MACHINES LAB: Comprehensive Resources for Understanding Machine Dynamics

- EDM LAB Equipment Collection: Essential EDM LAB Equipment for Your Needs

- Endocrinology Lab Equipment for Metabolism & Diabetes Research

- Engineering Institute Laboratory Equipment Collection - Engineering Laboratory Equipment

- Engineering Laboratory Equipment Collection: Essential Instruments and Tools

- ENT and Ophthalmic Conditions Collection

- Entomology Lab Equipment Essentials

- Flash Point Apparatus Collection for Accurate Testing

- Fluid Mechanics Lab Collection: Machinery Fluid Lab Experiments

- FMS LAB Collection - Explore Unique Innovatives

- Gastroenterology and Human Nutrition

- General Laboratory Equipment Collection for Efficient Research

- General Laboratory Equipment for Accurate Experiments and Analysis

- Genetics and Plant Breeding Equipment for Your Lab Needs

- Genetics and Plant Breeding Equipment: Essential Lab Tools for Research

- Haematology Lab Equipment: Essential Haematology Lab Instruments

- Handi Centrifuge Machines Collection

- Heart Models Collection: Unique Designs and Inspirations

- HEAT & MASS TRANSFER LAB

- Heating and Cooling Solutions for Optimal Comfort with Laboratory Equipment

- Herbal Products Quality Analysis in Herbal Testing Laboratory

- High-Quality Laboratory Equipment by Glomax - Leading Laboratory Equipment Manufacturer

- Hospital Equipment for Healthcare Professionals Collection

- Hospital Equipment Supplier Near Me: Your Local Source for Quality Medical Supplies

- Human Body Part Models Collection

- Human Skeleton Model - White PVC Plastic Educational Tool

- I.C. Engine Technology: Comprehensive Insights and Experiments in Internal Combustion Engine Lab

- Industrial Soil Equipment Collection: Essential Tools for Soil Management

- Kashmir Surgical Works - Quality Kashmir Surgical Instruments

- Knee Joint Model Collection

- Lab Chemicals: Essential Lab Chemical Supplies for Your Experiments

- Lab Equipment Collection: Essential Tools for Every Laboratory

- Lab Fabric Items Collection: Unique and Versatile Designs

- Lab Plasticware Supplies Collection for Laboratory Equipment and Supplies

- Lab Water Bath Collection: Essential Equipment for Precision Heating

- Laboratory Centrifuge Collection: Explore Top Laboratory Centrifuge Solutions

- Laboratory Consumables and Essential Laboratory Supplies

- Laboratory Equipment Collection: Essential Tools for Science and Research

- Laboratory Equipment Collection: Essential Tools for Your Experiments

- Laboratory Equipment Suppliers Ambala Cantt - Quality & Variety Available

- Laboratory Equipment Suppliers and Manufacturers Collection

- Laboratory Equipment Suppliers Delhi: Top Providers in the Capital

- Laboratory Equipment Suppliers India: Your Trusted Source

- Laboratory Equipment Suppliers Jaipur: Top Providers in the City

- Laboratory Equipment: Essential Tools for Every Laboratory

- Laboratory Glassware and Chemicals for Your Collection

- Laboratory Instruments Manufacturers Ambala Cantt

- Labpro Banner 60% Collection

- Labpro Banner Collection - Elevate Your Space with Unique Designs

- Labpro international

- Live Stock Management Equipment for Production Management Lab

- Livestock Production Management: Strategies for Effective Livestock and Production Management

- MATERIAL SCIENCE LAB - Explore Innovations in Material Science Lab

- Measurement and Metrology Lab Collection

- Measuring Tools for Precision: Accurate Measurements and Precision

- Mechanical Engineering Techniques: A Comprehensive Collection

- Medical laboratory equipment suppliers

- Medical Mannequin Collection for Training and Education

- Medical Supplies and Products Collection

- Mega Offers Discounts: Unbeatable Deals and Discounts Collection

- Melting Point Apparatus Collection

- Metrological Lab Equipment for Accurate Measurements and Testing

- Microbiological Diagnostic Equipment for Accurate Testing

- Microbiology and Pharmacology Equipment Collection

- Microbiology Laboratory Equipment and Zoology Lab Equipment

- Microcentrifuge Collection: Essential Tools for Precision Lab Work

- Micrometer: Explore Our Unique Micrometers Collection

- Micropipettes for Lab Use Collection

- Microscopes for Tiny Details: Explore the World of Tiny Details

- Milk Testing Equipment Collection: High-Quality Solutions for Accurate Results

- Mushroom Lab Equipment for Cultivation and Research

- Nephrology Lab Equipment: Essential Tools for Renal Research

- Nursing Lab Equipment Collection for Nursing College

- Nursing Lab Equipment for Nursing Department Collection

- Obstetrics and Gynaecology Equipment for Enhanced Care in Lab Settings

- Offer Zone: Exclusive Deals and Discounts Collection

- Orthopaedics Lab Equipment Collection

- OSAW Industrial Products Pvt Ltd - Quality Industrial Solutions

- Otorhinolaryngology Lab Equipment Collection

- Paediatrics Lab Equipment for Accurate Diagnosis and Care

- Pathology Lab Equipment for Accurate Diagnostics

- Pediatric Lab Equipment: Essential Tools for Child Healthcare

- PERMANENT SLIDES Collection for Lasting Impact

- pH meters for research - Top-Rated pH Meters for Accurate Testing

- Pharma Analysis Equipment for Laboratory Use

- Pharma Lab Equipment Collection for Enhanced Research Productivity

- Pharmaceutical and Research Lab Equipment Collection

- PHARMACEUTICAL BIOTECHNOLOGY EQUIPMENT

- Pharmaceutical Chemistry Lab Equipment Collection

- Pharmaceutics Laboratory Equipment Collection

- Pharmacognosy Lab Equipment Collection

- Pharmacology Lab Equipment: Essential Pharmacology Lab Tools

- Pharmacy Lab Equipment Suppliers for Quality Pharmacy College Tools and Supplies

- Pharmacy Laboratory Equipment Collection

- Physical Pharmacy Physics Lab Equipment Collection

- Physics Discount Items - 60% Off Select Products

- Physics Lab: Engaging Physics Lab Experiments for All Levels

- Physiology Lab Equipment for Essential Experiments

- Plant Pathology Microbiology Lab Collection

- product Offers 2024

- Profile Projectors: Precision Measurement Tools for Accurate Profile Analysis

- Pusher Centrifuge Collection: Innovative Solutions for Efficient Separation

- RADICAL SCIENTIFIC EQUIPMENTS PVT LTD - Radical Scientific Equipment Collection

- Refrigerated Centrifuge Suppliers and Manufacturers Collection

- REFRIGERATION & AIR CONDITIONING LAB

- Reproductive Biology lab equipment

- Research Section Lab Equipment - Essential Research Lab Equipment for Your Needs

- Rheumatology Lab Equipment and Rheumatology Lab Supplies

- Rheumatology Lab Tools for Accurate Diagnosis and Efficient Testing

- School and College Equipment Collection

- School and College University Products Collection for All Your Needs

- school lab equipment manufacturers in india

- Science Laboratory Equipment Collection for All Your Needs

- Scifa Laboratory Equipment: Innovative Solutions for Your Lab Needs

- SCITECH SCIENTIFICS: Advancing Scitech Scientific Research

- Seed Technology Collection: Innovations in Seed Technology

- Seed Technology Lab Equipment for Advanced Seed Technology Equipment Solutions

- Silica Gel Collection: Unique and Versatile Silica Gel Products

- Skull Models Collection: Unique and Intricate Designs

- Soil Testing Instruments Collection

- soil testing lab equipment list

- Soxhlet Extraction Solutions for Efficient Solvent Extraction Apparatus

- Span Automation - Span Automation Solutions for Efficient Processes

- spectrophotometer

- Strength of Materials Lab: Unleashing Structural Integrity

- Table Top Centrifuge Collection: Premium Table Top Centrifuges for Precision Lab Use

- Testing Equipment Collection

- Tiles Ceramic Laboratory Equipment: Optimize Your Ceramic Laboratory Tiles Equipment for Effective Analysis

- Top Laboratory Fume Hood Manufacturers in India - Leading Laboratory Fume Hood Manufacturers India

- Types of Masks: Explore Various Types of Masks

- Types of Microscopes: A Comprehensive Guide to Different Microscope Types

- Urology lab equipment

- Veterinary Lab Products for Optimal Veterinary Sciences Lab Solutions

- Zoology Lab Equipment: Essential Zoology Lab Instruments

Recent Articles

Tag Cloud

Top Sellers

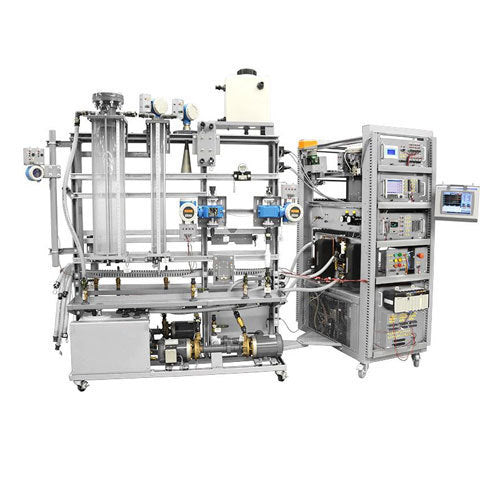

Process Control Systems: Enhancing Efficiency in Industrial Automation

Understanding Process Control Systems in Industrial Automation

Process control systems play a crucial role in enhancing efficiency in industrial automation. These systems are designed to monitor and control various industrial processes, ensuring that they operate at optimal levels. In today’s fast-paced manufacturing environments, having an effective process control system is essential for maintaining productivity and quality.

At the heart of process control systems are various technologies and methodologies that allow for real-time monitoring and adjustment of processes. This involves the use of sensors, controllers, and actuators that work together to maintain desired operational parameters. By utilizing these technologies, industries can achieve greater efficiency, reduce waste, and improve the overall performance of their operations.

One of the primary functions of process control systems is to ensure that production processes remain stable. Stability is critical in industrial environments, as fluctuations in process variables can lead to product defects, increased downtime, and safety hazards. Automated control loops, a key component of process control systems, help maintain this stability. These loops continuously assess process variables and make necessary adjustments to keep them within predefined limits.

The implementation of process control systems can lead to significant benefits for industrial operations. For instance, they can help reduce energy consumption by optimizing the use of machinery and equipment. This not only lowers operational costs but also contributes to environmental sustainability. Moreover, by providing the capability to quickly respond to changes in demand or process conditions, process control systems enhance the agility of manufacturing operations, allowing them to better adapt to market changes.

Another advantage of process control systems is their ability to facilitate data collection and analysis. With the integration of advanced analytics and data visualization tools, industries can gain insights into their operations that were previously not accessible. This data-driven approach enables organizations to make informed decisions based on real-time information, leading to continuous improvement in processes and operational efficiency.

In addition to traditional control methods, modern process control systems also leverage technologies such as artificial intelligence and machine learning. These advanced technologies can enhance predictive maintenance, helping to identify potential equipment failures before they occur. By minimizing unexpected downtime, organizations can maintain high levels of productivity and reduce maintenance costs, further improving their operational efficiency.

Training and education also play a vital role in maximizing the benefits of process control systems. Organizations must invest in educating their workforce on the functionality and capabilities of these systems. Skilled operators and engineers who understand the intricacies of process control systems can make better use of the technology, leading to more effective operations.

Furthermore, simulation and modeling tools are increasingly being utilized within the realm of process control systems. These tools enable organizations to test and visualize different process scenarios without disrupting actual production. By simulating various conditions, companies can evaluate potential improvements and identify the optimal settings for their operations.

As industries continue to evolve, the importance of process control systems will only increase. Innovations in technology will drive further advancements in automation, making these systems more sophisticated and capable of handling complex operational challenges. Organizations that embrace these innovations will position themselves favorably in competitive markets.

In conclusion, process control systems are fundamental to enhancing efficiency in industrial automation. By providing real-time monitoring and control, these systems contribute to increased productivity, reduced waste, and improved operational performance. As the manufacturing landscape continues to change, embracing process control systems will be key to achieving sustained success and competitiveness.

Top Suppliers

Collections

- Dairy products

- Milk Testing Equipment

- physics lab

- Laboratory And Scientific Equi...

- microscopes

- ENT AND OPHTHALMIC

- measuring tools

- Centrifuge machine

- Micrometer

- Micropipette

- Silica Gel

- BOTANY PERMANENT MICRO-PREPARE...

- PERMANENT SLIDES

- centrifuge machine

- mask - type of mask

- medical products

- bod incubator

- Lab Chemical

- Do meter

- Lab Fabric items

- dental Autoclave

- medical mannequin

- White PVC Plastic Human Skelet...

- Human Body Part Models

- Heart Models

- Knee Joint Model

- Skull Models

- Laboratory Centrifuge

- Handi Centrifuges

- Microcentrifuge

- Table Top Centrifuge

- Digital Centrifuge Machine

- Pusher Centrifuge

- Laboratory Consumables

- Melting Point Apparatus

- Soxhlet Extraction Apparatus

- Distilling Apparatus

- Chemistry Lab Apparatus

- Chromatography Apparatus

- Diffusion Cell Apparatus

- Flash Point Apparatus

- Science Laboratory Equipment

- Profile Projectors

- Engineering Laboratory Equipme...

- Types of Microscopes

- General Laboratory Equipment

- Heating & Cooling Products

- Hospital equipment

- Testing Equipment

- Clean Air Equipment

- Engineering & Institute labora...

- HEAT & MASS TRANSFER LAB

- REFRIGERATION & AIR CONDITIONI...

- I.C. ENGINE LAB

- FLUID MECHANICS AND MACHINERY ...

- STRENGTH OF MATERIALS LAB

- EDM LAB equipment

- MATERIAL SCIENCE LAB

- FMS LAB

- CAD LAB

- AUTOMOBILE LAB

- MEASUREMENT & METROLOGY LAB

- DYNAMICS OF MACHINES LAB

- CENTRAL WORKSHOP

- Aerospace Engineering lab Equi...

- Biological Sciences lab Equipm...

- Chemical Engineering Equipment

- Civil Engineering

- Mechanical Engineering

- School And College University ...

- Lab Glassware & Chemical Items

- Zoology Lab Equipment

- Microbiology laboratory equipm...

- Chemistry Lab Products

- Botany Lab Product

- Biological Lab Equipment

- Department Of Anatomy Lab Equi...

- College of Nursing Lab Equipme...

- Endocrinology, Metabolism & Di...

- Haematology Lab Equipment

- Orthopaedics lab equipment

- Pediatric lab equipment

- Pathology lab equipment

- Physiology lab equipment

- Rheumatology lab equipment

- Urology lab equipment

- Obstetrics and Gynaecology lab...

- Otorhinolaryngology lab equipm...

- Pharmacology lab equipment

- Anatomy lab equipment

- Research Section lab equipment

- Pharmaceutical & Research Lab ...

- Physical Pharmacy Lab equipmen...

- Pharma Biology Laboratory Lab ...

- General Laboratory Equipment

- School And College University ...

- Medical College Lab equipment

- Biomedical Engineering Lab Equ...

- Biostatistics Lab Equipment

- Cardiology Lab Equipment

- College of Nursing Lab Equipme...

- Gastroenterology and Human Nut...

- Gastroenterology and Human Nut...

- Nursing Department lab equipme...

- Paediatrics lab equipment

- Reproductive Biology lab equip...

- Rheumatology lab equipment

- Biochemistry lab equipment

- Biophysics lab equipment

- Biotechnology lab equipment

- Centre for Community Medicine ...

- Nephrology lab equipment

- Pharmaceutical Chemistry Lab E...

- Microbiology & Pharmacology La...

- D Pharmacy equipment

- B pharmacy Equipments

- Pharmaceutics Laboratory Equip...

- Pharma Analysis Laboratory Equ...

- Animal House lab Equipment

- Pharmacognosy Laboratory Equip...

- Pharmacy laboratories equipmen...

- DEPARTMENT OF PHARMACOLOGY Equ...

- DEPARTMENT OF PHARMACOGNOSY Eq...

- DEPARTMENT OF P'CEUTICAL CHEMI...

- DEPARTMENT OF P'CEUTICS Equipm...

- PHARMACEUTICAL BIOTECHNOLOGY E...

- Livestock & Production Managem...

- Veterinary Sciences Lab Produc...

- Live Stock & Production Manage...

- Genetics and Plant Breeding la...

- Biotechnology lab equipment

- Seed Technology Lab Equipment

- Genetics and Plant Breeding la...

- Biotechnology

- Seed Technology

- Soil Science & Soil Water Cons...

- Entomology Lab equipment

- Agronomy Lab Equipment

- Metrological Lab Equipment

- Plant Pathology & Microbiology...

- Dental Equipment

- Microbiological Diagnostic Equ...

- Industrial & Soil Equipment

- Accessories

- Mega Offer

- Offer Zone

- Tiles Ceramic Laboratory Equip...

- analytical lab Equipment

- ayurvedic drug testing laborat...

- ayurvedic pharmacy instruments

- herbal testing laboratory

- mushroom lab Equipment

- lab plasticware

- agriculture Lab Equipment

- Agriculture College Lab Equipm...

- Labpro Banner 60%

- Labpro banner

- physics 60% Discount

- Hospital equipment supplier Ne...

Top Suppliers

Blog Posts

- green laser Light...

- Student Stereo Mi...

- Binocular Microsc...

- Laboratory Equipm...

- Prokaryos lab and...

- Pharmacy Lab

- Micro lab Laminar...

- MILK TESTING EQUI...

- Micrometer

- Centrifuge Machin...

- Chemistry Lab Equ...

- Agricultural coll...

- full body sanitiz...

- hydrometer for wi...

- Portable Bottle f...

- Egg Incubator

- Laboratorydeal of...

- A complete list o...

- different types o...

- Uses of Microscop...

- Tags: Actuators Alarm management Control algorithms Control strategies Control unit DCS (Distributed Control System) Efficiency improvement Fault detection and diagnosis Feedback control Feedforward control Human-machine interface (HMI) Industrial automation PLC (Programmable Logic Controller) Process control systems Process variables Real-time monitoring Safety enhancement SCADA (Supervisory Control and Data Acquisition) Setpoints System optimization