Categories

- 10 Best Bod Incubator 2025 at Lowest Price

- 10 Best Compound Microscopes 2025 at Lowest Prices

- 10 Best Lab Chemicals 2025 at Lowest Prices

- 10 Best Lab Equipment Suppliers 2025 - Lowest Prices Available

- 10 Best Lab Microscopes 2025

- 10 Best Microbiology Lab Equipment 2025 at Lowest Prices

- 10 Best Refrigerator Mortuary Freezer India

- 10 Best Student Microscopes 2025 at Lowest Prices

- 10 Best Vertical Autoclaves 2025 - Vertical Autoclaves Best Prices 2025

- Accessories Collection: Trendy and Essential Items

- Aerospace Engineering Equipment Collection for Optimal Research and Innovation

- Agriculture Lab Equipment for Precision Farming and Research

- Agriculture Lab Equipment Suppliers for Agriculture College Needs

- Agronomy Lab Equipment for Precise Agricultural Research

- analytical lab equipment for precision testing and research

- Anatomy Lab Equipment Collection for Education and Research

- Animal House Lab Equipment: Essential Tools for Research

- AUTOMOBILE LAB: Explore Innovations in Automotive Engineering

- ayurvedic drug testing laboratory for quality assurance and effectiveness

- Ayurvedic Lab Equipment Suppliers and Manufacturers for Colleges

- Ayurvedic Pharmacy Instruments: Essential Ayurvedic Pharmacy Tools

- B Pharmacy Equipment Suppliers: Quality Supplies for Your Pharmacy

- B. D. Instrumentation India: Leading Solutions in Instrumentation

- Best Microscope for Students in India: Top Picks for Students

- Binocular Microscope Collection

- Biochemistry lab equipment

- Biological Lab Equipment Collection

- Biological Lab Equipment for Research and Experimentation in Biological Sciences

- Biology Lab Equipment

- Biomedical Engineering Lab Equipment

- Biophysics Lab Equipment for Research and Experiments - Essential Tools for Biophysics Studies

- Biostatistics Lab Equipment

- Biotechnology Collection: Innovative Advances in Biotechnology

- Biotechnology Lab Tools and Equipment for Advanced Research

- Biotechnology Lab Tools for Efficient Research and Innovation

- Borolab Scientific Glass Pvt. Ltd.

- Botany Lab Supplies for All Your Plant Research Needs

- Botany Permanent Micro-Prepared Slides Collection - Botany Micro-Prepared Slides

- CAD Lab Collection - Innovative Designs and Solutions

- Cardiology Lab Equipment

- Central Drug House Collection - CDH

- CENTRAL WORKSHOP Collection: Premium Tools and Equipment for Every Project

- Centre for Community Medicine Lab Equipment Collection

- Centrifuge Machine Collection: Explore Top Models and Features

- Centrifuge Machine Suppliers India - Quality and Reliability at Its Best

- Chemical Engineering Equipment Collection

- Chemistry equipment

- Chemistry Lab Apparatus - Essential Chemistry Lab Equipment

- Chromatography Apparatus Collection for Efficient Separation Techniques

- Civil Engineering Collection: Essential Resources and Insights

- Clean Air Equipment

- College of Nursing Lab Equipment

- D Pharmacy equipment

- Dairy Analysis Instruments: Essential Tools in the Dairy Lab Collection

- Dental Autoclave Cost and Price Analysis Collection

- Dental Equipment Supply and Tools for Professionals

- Department of Anatomy Lab Equipment – Essential Anatomy Lab Equipment for Students and Professionals

- DEPARTMENT OF P'CEUTICAL CHEMISTRY Equipment - Pharmaceutical Chemistry Equipment

- DEPARTMENT OF P'CEUTICS Equipment - Pharmaceutical Equipment Collection

- DEPARTMENT OF PHARMACOGNOSY Equipment - Essential Tools for Research and Analysis

- DEPARTMENT OF PHARMACOLOGY Equipment

- Diffusion Cell Apparatus: Understanding Its Applications and Benefits

- Digital Centrifuge Machine Collection

- Distillation Equipment: Essential Distillation Apparatus for Your Collection

- Do Meter Collection: Unique Designs and Innovative Styles

- DYNAMICS OF MACHINES LAB: Comprehensive Resources for Understanding Machine Dynamics

- EDM LAB Equipment Collection: Essential EDM LAB Equipment for Your Needs

- Endocrinology Lab Equipment for Metabolism & Diabetes Research

- Engineering Institute Laboratory Equipment Collection - Engineering Laboratory Equipment

- Engineering Laboratory Equipment Collection: Essential Instruments and Tools

- ENT and Ophthalmic Conditions Collection

- Entomology Lab Equipment Essentials

- Flash Point Apparatus Collection for Accurate Testing

- Fluid Mechanics Lab Collection: Machinery Fluid Lab Experiments

- FMS LAB Collection - Explore Unique Innovatives

- Gastroenterology and Human Nutrition

- General Laboratory Equipment Collection for Efficient Research

- General Laboratory Equipment for Accurate Experiments and Analysis

- Genetics and Plant Breeding Equipment for Your Lab Needs

- Genetics and Plant Breeding Equipment: Essential Lab Tools for Research

- Haematology Lab Equipment: Essential Haematology Lab Instruments

- Handi Centrifuge Machines Collection

- Heart Models Collection: Unique Designs and Inspirations

- HEAT & MASS TRANSFER LAB

- Heating and Cooling Solutions for Optimal Comfort with Laboratory Equipment

- Herbal Products Quality Analysis in Herbal Testing Laboratory

- High-Quality Laboratory Equipment by Glomax - Leading Laboratory Equipment Manufacturer

- Hospital Equipment for Healthcare Professionals Collection

- Hospital Equipment Supplier Near Me: Your Local Source for Quality Medical Supplies

- Human Body Part Models Collection

- Human Skeleton Model - White PVC Plastic Educational Tool

- I.C. Engine Technology: Comprehensive Insights and Experiments in Internal Combustion Engine Lab

- Industrial Soil Equipment Collection: Essential Tools for Soil Management

- Kashmir Surgical Works - Quality Kashmir Surgical Instruments

- Knee Joint Model Collection

- Lab Chemicals: Essential Lab Chemical Supplies for Your Experiments

- Lab Equipment Collection: Essential Tools for Every Laboratory

- Lab Fabric Items Collection: Unique and Versatile Designs

- Lab Plasticware Supplies Collection for Laboratory Equipment and Supplies

- Lab Water Bath Collection: Essential Equipment for Precision Heating

- Laboratory Centrifuge Collection: Explore Top Laboratory Centrifuge Solutions

- Laboratory Consumables and Essential Laboratory Supplies

- Laboratory Equipment Collection: Essential Tools for Science and Research

- Laboratory Equipment Collection: Essential Tools for Your Experiments

- Laboratory Equipment Suppliers Ambala Cantt - Quality & Variety Available

- Laboratory Equipment Suppliers and Manufacturers Collection

- Laboratory Equipment Suppliers Delhi: Top Providers in the Capital

- Laboratory Equipment Suppliers India: Your Trusted Source

- Laboratory Equipment Suppliers Jaipur: Top Providers in the City

- Laboratory Equipment: Essential Tools for Every Laboratory

- Laboratory Glassware and Chemicals for Your Collection

- Laboratory Instruments Manufacturers Ambala Cantt

- Labpro Banner 60% Collection

- Labpro Banner Collection - Elevate Your Space with Unique Designs

- Labpro international

- Live Stock Management Equipment for Production Management Lab

- Livestock Production Management: Strategies for Effective Livestock and Production Management

- MATERIAL SCIENCE LAB - Explore Innovations in Material Science Lab

- Measurement and Metrology Lab Collection

- Measuring Tools for Precision: Accurate Measurements and Precision

- Mechanical Engineering Techniques: A Comprehensive Collection

- Medical laboratory equipment suppliers

- Medical Mannequin Collection for Training and Education

- Medical Supplies and Products Collection

- Mega Offers Discounts: Unbeatable Deals and Discounts Collection

- Melting Point Apparatus Collection

- Metrological Lab Equipment for Accurate Measurements and Testing

- Microbiological Diagnostic Equipment for Accurate Testing

- Microbiology and Pharmacology Equipment Collection

- Microbiology Laboratory Equipment and Zoology Lab Equipment

- Microcentrifuge Collection: Essential Tools for Precision Lab Work

- Micrometer: Explore Our Unique Micrometers Collection

- Micropipettes for Lab Use Collection

- Microscopes for Tiny Details: Explore the World of Tiny Details

- Milk Testing Equipment Collection: High-Quality Solutions for Accurate Results

- Mushroom Lab Equipment for Cultivation and Research

- Nephrology Lab Equipment: Essential Tools for Renal Research

- Nursing Lab Equipment Collection for Nursing College

- Nursing Lab Equipment for Nursing Department Collection

- Obstetrics and Gynaecology Equipment for Enhanced Care in Lab Settings

- Offer Zone: Exclusive Deals and Discounts Collection

- Orthopaedics Lab Equipment Collection

- OSAW Industrial Products Pvt Ltd - Quality Industrial Solutions

- Otorhinolaryngology Lab Equipment Collection

- Paediatrics Lab Equipment for Accurate Diagnosis and Care

- Pathology Lab Equipment for Accurate Diagnostics

- Pediatric Lab Equipment: Essential Tools for Child Healthcare

- PERMANENT SLIDES Collection for Lasting Impact

- pH meters for research - Top-Rated pH Meters for Accurate Testing

- Pharma Analysis Equipment for Laboratory Use

- Pharma Lab Equipment Collection for Enhanced Research Productivity

- Pharmaceutical and Research Lab Equipment Collection

- PHARMACEUTICAL BIOTECHNOLOGY EQUIPMENT

- Pharmaceutical Chemistry Lab Equipment Collection

- Pharmaceutics Laboratory Equipment Collection

- Pharmacognosy Lab Equipment Collection

- Pharmacology Lab Equipment: Essential Pharmacology Lab Tools

- Pharmacy Lab Equipment Suppliers for Quality Pharmacy College Tools and Supplies

- Pharmacy Laboratory Equipment Collection

- Physical Pharmacy Physics Lab Equipment Collection

- Physics Discount Items - 60% Off Select Products

- Physics Lab: Engaging Physics Lab Experiments for All Levels

- Physiology Lab Equipment for Essential Experiments

- Plant Pathology Microbiology Lab Collection

- product Offers 2024

- Profile Projectors: Precision Measurement Tools for Accurate Profile Analysis

- Pusher Centrifuge Collection: Innovative Solutions for Efficient Separation

- RADICAL SCIENTIFIC EQUIPMENTS PVT LTD - Radical Scientific Equipment Collection

- Refrigerated Centrifuge Suppliers and Manufacturers Collection

- REFRIGERATION & AIR CONDITIONING LAB

- Reproductive Biology lab equipment

- Research Section Lab Equipment - Essential Research Lab Equipment for Your Needs

- Rheumatology Lab Equipment and Rheumatology Lab Supplies

- Rheumatology Lab Tools for Accurate Diagnosis and Efficient Testing

- School and College Equipment Collection

- School and College University Products Collection for All Your Needs

- school lab equipment manufacturers in india

- Science Laboratory Equipment Collection for All Your Needs

- Scifa Laboratory Equipment: Innovative Solutions for Your Lab Needs

- SCITECH SCIENTIFICS: Advancing Scitech Scientific Research

- Seed Technology Collection: Innovations in Seed Technology

- Seed Technology Lab Equipment for Advanced Seed Technology Equipment Solutions

- Silica Gel Collection: Unique and Versatile Silica Gel Products

- Skull Models Collection: Unique and Intricate Designs

- Soil Testing Instruments Collection

- soil testing lab equipment list

- Soxhlet Extraction Solutions for Efficient Solvent Extraction Apparatus

- Span Automation - Span Automation Solutions for Efficient Processes

- spectrophotometer

- Strength of Materials Lab: Unleashing Structural Integrity

- Table Top Centrifuge Collection: Premium Table Top Centrifuges for Precision Lab Use

- Testing Equipment Collection

- Tiles Ceramic Laboratory Equipment: Optimize Your Ceramic Laboratory Tiles Equipment for Effective Analysis

- Top Laboratory Fume Hood Manufacturers in India - Leading Laboratory Fume Hood Manufacturers India

- Types of Masks: Explore Various Types of Masks

- Types of Microscopes: A Comprehensive Guide to Different Microscope Types

- Urology lab equipment

- Veterinary Lab Products for Optimal Veterinary Sciences Lab Solutions

- Zoology Lab Equipment: Essential Zoology Lab Instruments

Recent Articles

Tag Cloud

Top Sellers

Mechanical Engineering Lab Tools: Essential Equipment for Success

Mechanical Engineering Lab Tools: Key Instruments for Effective Learning

Mechanical Engineering Lab Tools are an essential part of any engineering curriculum, providing students with hands-on experience that is critical for understanding theoretical concepts. In a mechanical engineering lab, students engage with various tools and equipment that allow them to conduct experiments, perform simulations, and test different engineering principles. The importance of mechanical engineering lab tools cannot be overstated; they bridge the gap between textbook knowledge and practical application.

Many mechanical engineering programs incorporate lab sessions as a core component of their curriculum, usually focusing on several key areas such as thermodynamics, fluid mechanics, materials science, and dynamics. To ensure students maximize their learning experience, specific lab tools are required. Here, we categorize these tools based on their functionalities and the practical applications they support.

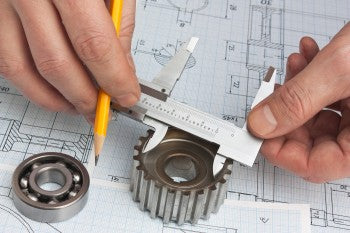

Measurement Tools

Measurement tools are fundamental for any mechanical engineering lab. Precision is essential in engineering, and having the right measuring instruments can significantly impact the accuracy of experiments. Common measurement tools include:

- Calipers: Used for measuring the distance between two opposite sides of an object.

- Micrometers: Precision tools to measure small distances or thicknesses.

- Dial Gauges: Instruments that provide accurate measurements of distance and displacement.

- Pressure Gauges: Essential for experiments involving fluids and gases, measuring the pressure within a system.

Fabrication Tools

Fabrication tools are vital for any mechanical engineering lab, allowing students to create prototypes and components. These tools support hands-on learning and foster creativity. Common fabrication tools include:

- 3D Printers: Used to create prototypes from digital models, essential for rapid prototyping.

- Mills and Lathes: Machines that are used to cut and shape materials, providing a practical understanding of manufacturing processes.

- Welding Equipment: Tools essential for joining materials together, often used in fabrication projects.

- CNC Machines: Used for precise machining of parts, allowing for automation in the fabrication process.

Testing Equipment

Testing equipment plays a crucial role in the mechanical engineering lab, enabling students to test material properties and system performances. This category includes:

- Tensile Testing Machines: Used to determine the tensile strength of materials.

- Impact Testers: Equipment to measure the toughness of materials under sudden stress.

- Fatigue Testing Machines: Used to test materials under cyclic loading to understand their durability.

- Thermal Analysis Instruments: Used to study material behavior under temperature changes.

Simulation Software

In addition to physical tools, simulation software is also an integral part of modern mechanical engineering labs. These tools allow students to model and analyze complex systems without the need for physical prototypes. Key software includes:

- Finite Element Analysis (FEA) Software: Used for simulating how products react to real-world forces, vibration, heat, and other physical effects.

- Computational Fluid Dynamics (CFD) Software: Allows engineers to simulate fluid flow, heat transfer, and other fluid-related phenomena.

- Computer-Aided Design (CAD) Software: Essential for designing parts, assemblies, and detailed drawings.

Safety Equipment

Safety is paramount in any engineering lab. Providing proper safety gear and equipment is essential to protect students while they use mechanical engineering lab tools. Key safety equipment includes:

- Safety Goggles: Protects eyes from flying particles, chemicals, and other hazards.

- Gloves: Essential for handling materials, especially when working with chemicals or sharp objects.

- Lab Coats: Protects clothing and skin from spills and contaminants.

- Fire Extinguishers: Mandatory safety equipment in any engineering lab due to the potential hazards.

In conclusion, a well-equipped mechanical engineering lab is vital for preparing students for their future careers. The combination of mechanical engineering lab tools—including measurement devices, fabrication tools, testing equipment, simulation software, and safety gear—ensures that students can effectively learn, experiment, and innovate. Successful engineering education relies heavily on the hands-on experience and practical knowledge gained through the use of these essential tools, making them indispensable in any educational program focused on mechanical engineering.

Top Suppliers

Collections

- Dairy products

- Milk Testing Equipment

- physics lab

- Laboratory And Scientific Equi...

- microscopes

- ENT AND OPHTHALMIC

- measuring tools

- Centrifuge machine

- Micrometer

- Micropipette

- Silica Gel

- BOTANY PERMANENT MICRO-PREPARE...

- PERMANENT SLIDES

- centrifuge machine

- mask - type of mask

- medical products

- bod incubator

- Lab Chemical

- Do meter

- Lab Fabric items

- dental Autoclave

- medical mannequin

- White PVC Plastic Human Skelet...

- Human Body Part Models

- Heart Models

- Knee Joint Model

- Skull Models

- Laboratory Centrifuge

- Handi Centrifuges

- Microcentrifuge

- Table Top Centrifuge

- Digital Centrifuge Machine

- Pusher Centrifuge

- Laboratory Consumables

- Melting Point Apparatus

- Soxhlet Extraction Apparatus

- Distilling Apparatus

- Chemistry Lab Apparatus

- Chromatography Apparatus

- Diffusion Cell Apparatus

- Flash Point Apparatus

- Science Laboratory Equipment

- Profile Projectors

- Engineering Laboratory Equipme...

- Types of Microscopes

- General Laboratory Equipment

- Heating & Cooling Products

- Hospital equipment

- Testing Equipment

- Clean Air Equipment

- Engineering & Institute labora...

- HEAT & MASS TRANSFER LAB

- REFRIGERATION & AIR CONDITIONI...

- I.C. ENGINE LAB

- FLUID MECHANICS AND MACHINERY ...

- STRENGTH OF MATERIALS LAB

- EDM LAB equipment

- MATERIAL SCIENCE LAB

- FMS LAB

- CAD LAB

- AUTOMOBILE LAB

- MEASUREMENT & METROLOGY LAB

- DYNAMICS OF MACHINES LAB

- CENTRAL WORKSHOP

- Aerospace Engineering lab Equi...

- Biological Sciences lab Equipm...

- Chemical Engineering Equipment

- Civil Engineering

- Mechanical Engineering

- School And College University ...

- Lab Glassware & Chemical Items

- Zoology Lab Equipment

- Microbiology laboratory equipm...

- Chemistry Lab Products

- Botany Lab Product

- Biological Lab Equipment

- Department Of Anatomy Lab Equi...

- College of Nursing Lab Equipme...

- Endocrinology, Metabolism & Di...

- Haematology Lab Equipment

- Orthopaedics lab equipment

- Pediatric lab equipment

- Pathology lab equipment

- Physiology lab equipment

- Rheumatology lab equipment

- Urology lab equipment

- Obstetrics and Gynaecology lab...

- Otorhinolaryngology lab equipm...

- Pharmacology lab equipment

- Anatomy lab equipment

- Research Section lab equipment

- Pharmaceutical & Research Lab ...

- Physical Pharmacy Lab equipmen...

- Pharma Biology Laboratory Lab ...

- General Laboratory Equipment

- School And College University ...

- Medical College Lab equipment

- Biomedical Engineering Lab Equ...

- Biostatistics Lab Equipment

- Cardiology Lab Equipment

- College of Nursing Lab Equipme...

- Gastroenterology and Human Nut...

- Gastroenterology and Human Nut...

- Nursing Department lab equipme...

- Paediatrics lab equipment

- Reproductive Biology lab equip...

- Rheumatology lab equipment

- Biochemistry lab equipment

- Biophysics lab equipment

- Biotechnology lab equipment

- Centre for Community Medicine ...

- Nephrology lab equipment

- Pharmaceutical Chemistry Lab E...

- Microbiology & Pharmacology La...

- D Pharmacy equipment

- B pharmacy Equipments

- Pharmaceutics Laboratory Equip...

- Pharma Analysis Laboratory Equ...

- Animal House lab Equipment

- Pharmacognosy Laboratory Equip...

- Pharmacy laboratories equipmen...

- DEPARTMENT OF PHARMACOLOGY Equ...

- DEPARTMENT OF PHARMACOGNOSY Eq...

- DEPARTMENT OF P'CEUTICAL CHEMI...

- DEPARTMENT OF P'CEUTICS Equipm...

- PHARMACEUTICAL BIOTECHNOLOGY E...

- Livestock & Production Managem...

- Veterinary Sciences Lab Produc...

- Live Stock & Production Manage...

- Genetics and Plant Breeding la...

- Biotechnology lab equipment

- Seed Technology Lab Equipment

- Genetics and Plant Breeding la...

- Biotechnology

- Seed Technology

- Soil Science & Soil Water Cons...

- Entomology Lab equipment

- Agronomy Lab Equipment

- Metrological Lab Equipment

- Plant Pathology & Microbiology...

- Dental Equipment

- Microbiological Diagnostic Equ...

- Industrial & Soil Equipment

- Accessories

- Mega Offer

- Offer Zone

- Tiles Ceramic Laboratory Equip...

- analytical lab Equipment

- ayurvedic drug testing laborat...

- ayurvedic pharmacy instruments

- herbal testing laboratory

- mushroom lab Equipment

- lab plasticware

- agriculture Lab Equipment

- Agriculture College Lab Equipm...

- Labpro Banner 60%

- Labpro banner

- physics 60% Discount

- Hospital equipment supplier Ne...

Top Suppliers

Blog Posts

- green laser Light...

- Student Stereo Mi...

- Binocular Microsc...

- Laboratory Equipm...

- Prokaryos lab and...

- Pharmacy Lab

- Micro lab Laminar...

- MILK TESTING EQUI...

- Micrometer

- Centrifuge Machin...

- Chemistry Lab Equ...

- Agricultural coll...

- full body sanitiz...

- hydrometer for wi...

- Portable Bottle f...

- Egg Incubator

- Laboratorydeal of...

- A complete list o...

- different types o...

- Uses of Microscop...

1. Valve timing diagram test equipment ( 1No.s)

2. Redwood Viscometer( 1No.s)

Please give your best quotation on your letter head.

Our address:

Head,

Department of Mechanical Engineering,

University College of Engineering,

Osmania University, Hyderabad-500076

Regards

Head

Dept. of Mech. Engg.