Process Engineering Education

Process Engineering Education is essential for cultivating the next generation of engineers who will design and optimize processes in various industries. As our world becomes increasingly complex, understanding the core principles of process engineering has never been more critical. Process engineering focuses on the design, operation, control, and optimization of chemical, physical, and biological processes. It encompasses a wide array of topics including thermodynamics, fluid mechanics, heat and mass transfer, and reaction engineering.

Process engineering is a specialized discipline within chemical engineering that focuses on designing, optimizing, and managing industrial processes. It involves the application of scientific principles, engineering knowledge, and mathematical techniques to develop efficient and cost-effective processes for the production of various products.

The teaching process engineering typically involves several key components:

-

Fundamentals of Process Engineering: The curriculum starts with the fundamentals of process engineering, which includes topics such as material and energy balances, thermodynamics, fluid mechanics, and heat transfer. Students learn about the basic principles and concepts that form the foundation of process engineering.

-

Process Design and Analysis: This aspect of teaching process engineering focuses on the design and analysis of chemical and industrial processes. Students learn how to conceptualize, develop, and evaluate process flow diagrams, equipment sizing, and process simulations using specialized software tools. They also learn about process safety considerations and how to mitigate potential hazards.

-

Reaction Engineering: Reaction engineering is a crucial component of process engineering, particularly for industries that involve chemical reactions. Students learn about reaction kinetics, reactor design, and catalyst selection. They study various types of reactors, such as batch, continuous, and fixed-bed reactors, and understand the factors influencing reaction rates and conversion.

-

Separation Processes: Separation processes are essential for isolating and purifying desired products from mixtures. Students learn about various separation techniques, including distillation, absorption, extraction, filtration, and crystallization. They study the principles behind each technique, their applications, and the design considerations for efficient separation.

-

Process Control and Optimization: Teaching process engineering involves imparting knowledge about process control systems and optimization techniques. Students learn how to design and implement control systems to maintain desired process conditions, ensure product quality, and enhance efficiency. They also explore optimization methods to improve process performance, reduce energy consumption, and minimize waste generation.

-

Process Safety and Environmental Considerations: Process engineers are responsible for ensuring the safety of operations and minimizing environmental impact. Teaching process engineering includes educating students about process safety standards, hazard identification, risk assessment, and emergency response protocols. They also learn about environmental regulations, sustainability practices, and waste management strategies.

-

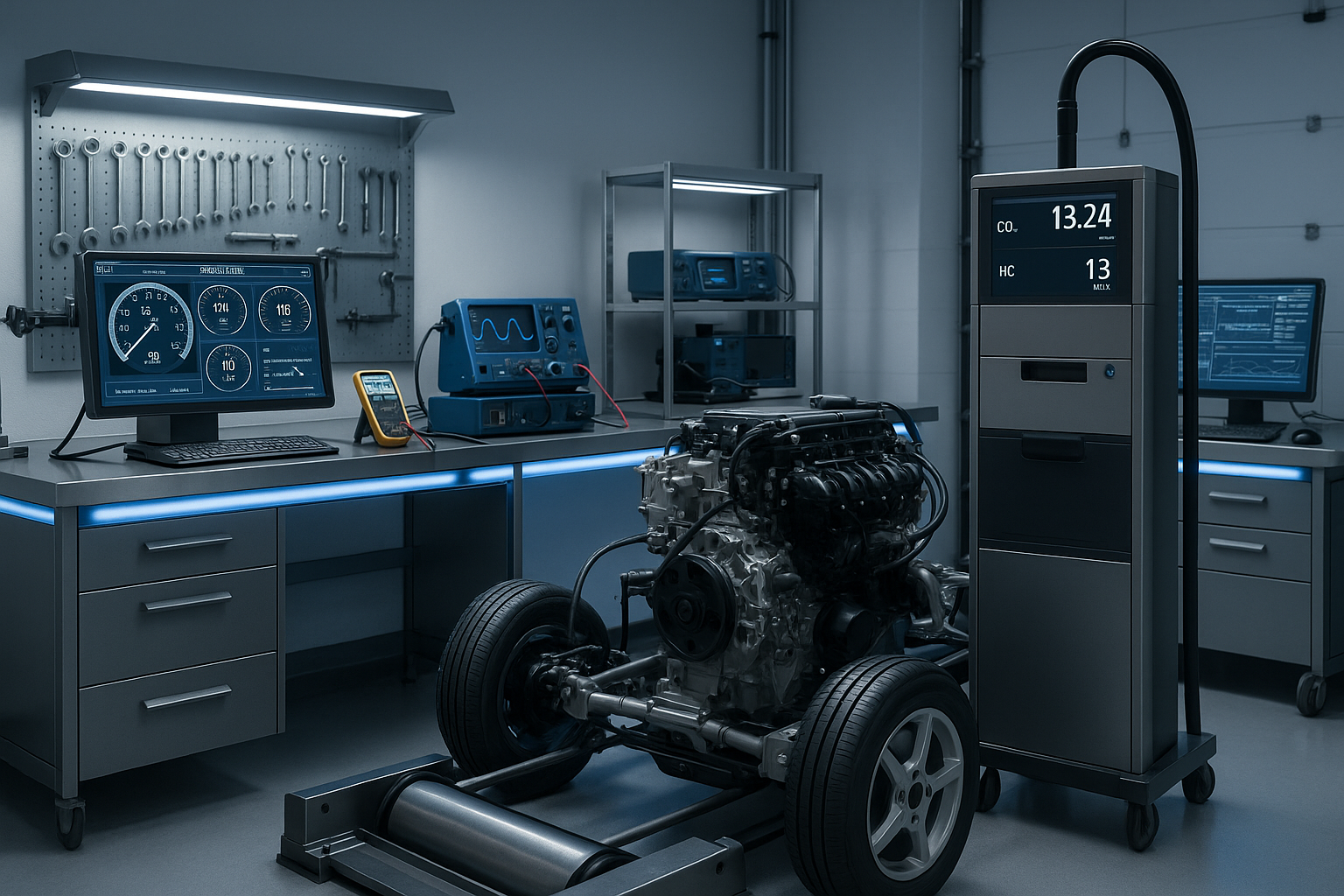

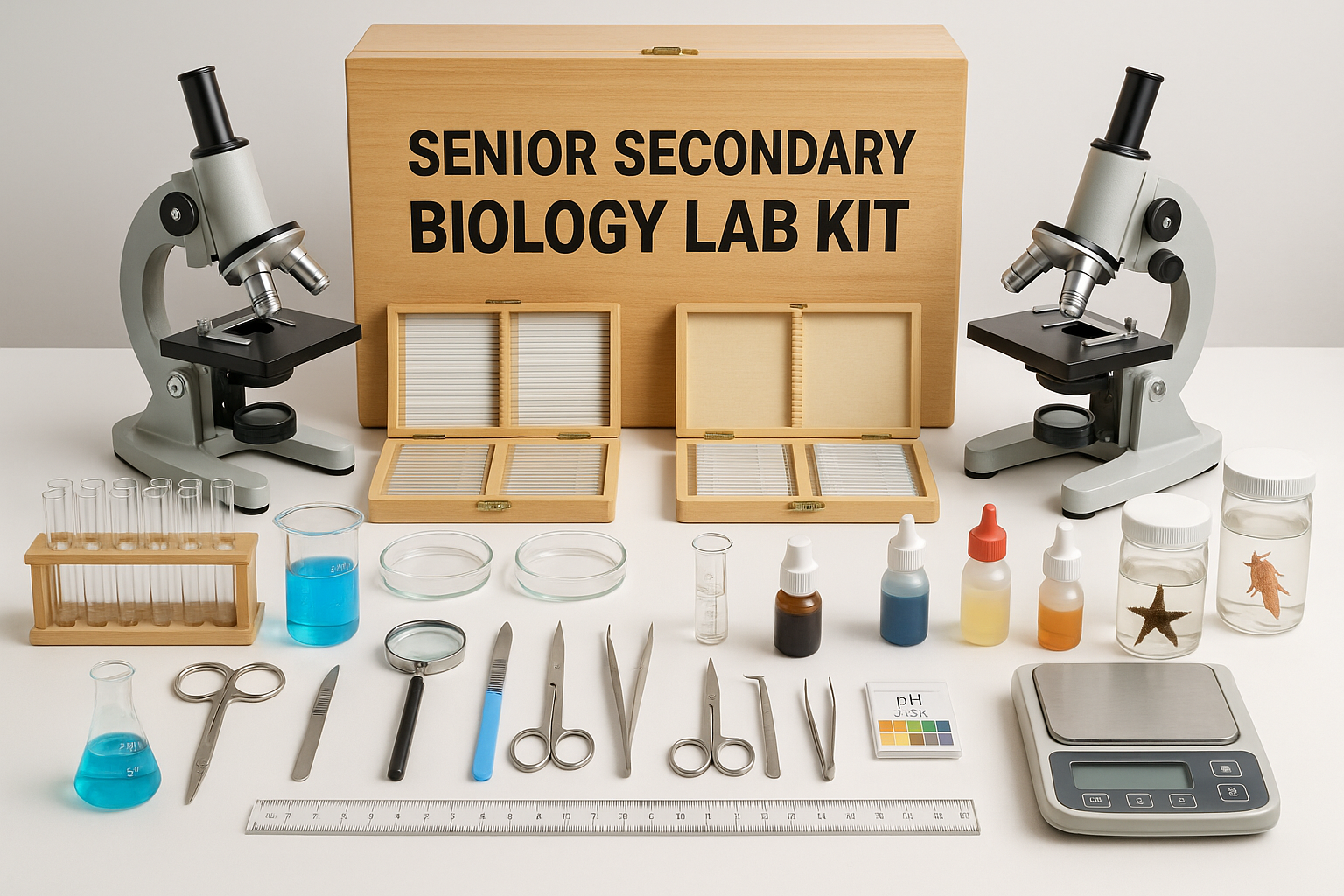

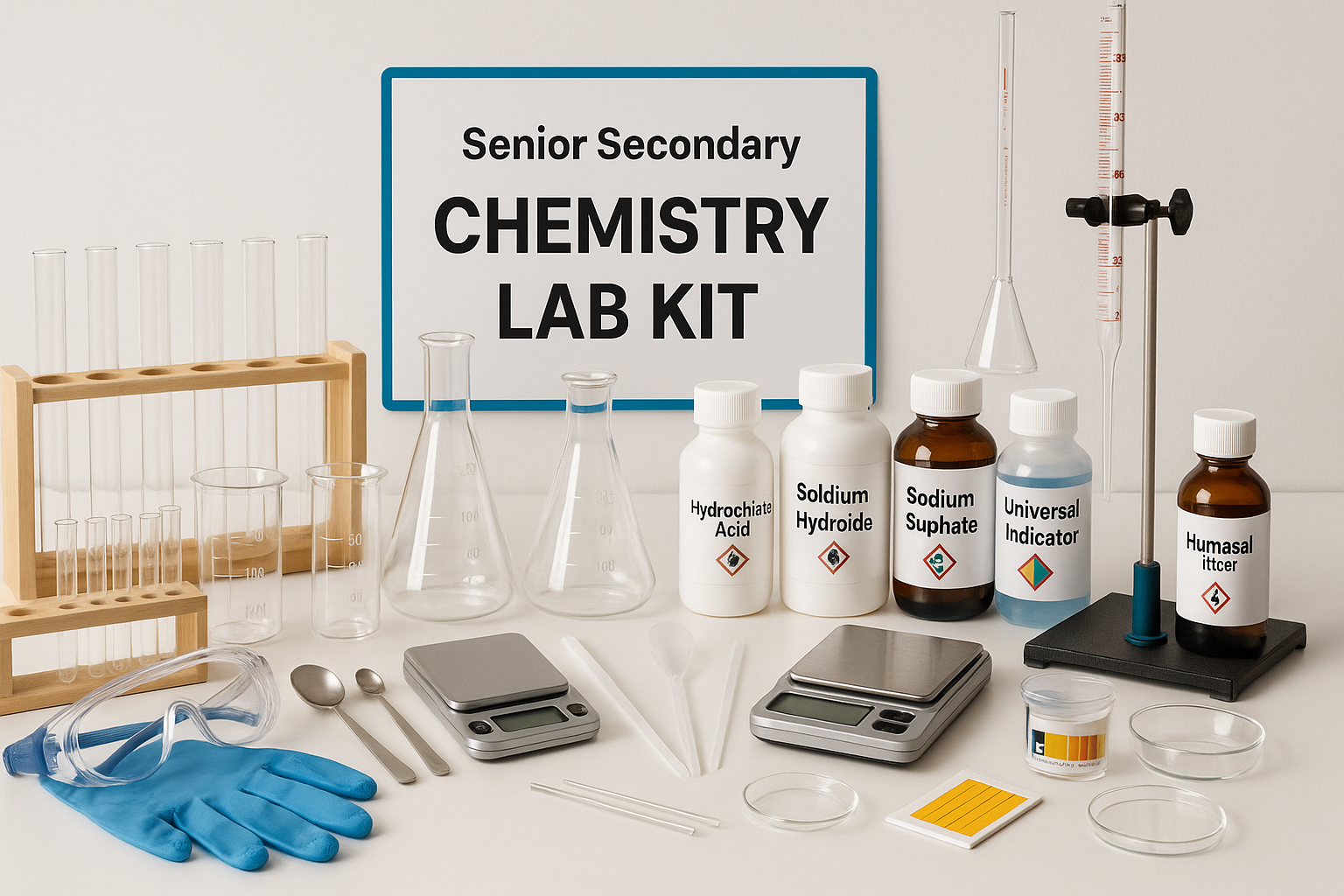

Case Studies and Practical Applications: To provide real-world context, teaching process engineering often includes case studies and practical applications. Students analyze and solve engineering problems related to process design, optimization, troubleshooting, and plant operations. They may also engage in laboratory experiments or industrial internships to gain hands-on experience.

Throughout the teaching process, students may work on individual or group projects, participate in discussions and seminars, and collaborate with industry professionals to develop a comprehensive understanding of process engineering principles and their applications. Practical experience and exposure to industry practices are essential for students to become proficient process engineers capable of designing and managing complex industrial processes efficiently.

LABORATORYDEAL India maintains a good quality assurance of all its products and provides lab equipment at affordable and eco-friendly rates. The company provides lab equipment throughout and outside the country and has a network of dealers and distributors in various states, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal

To effectively teach process engineering, educators must adopt a multidisciplinary approach that combines theoretical knowledge with practical applications. This ensures that students not only understand the fundamental concepts but also gain hands-on experience that prepares them for real-world challenges. Incorporating case studies, simulations, and project-based learning into the curriculum allows students to apply what they learn in a meaningful way, bridging the gap between theory and practice.

One effective method of enhancing process engineering education is through the integration of modern technology. The use of software tools and simulation programs allows students to visualize complex processes and understand the intricacies involved. For instance, software like Aspen Plus or MATLAB can be employed to model chemical processes, enabling students to experiment with various parameters and observe the outcomes. By utilizing these tools in the classroom, educators can foster a more engaging and interactive learning environment.

Moreover, industry partnerships are pivotal for enriching process engineering education. Collaborating with industry professionals can provide students with insights into the latest technologies and methodologies used in the field. Guest lectures, internships, and collaborative projects can enhance the learning experience and help students build valuable networks. Exposure to real-world scenarios can also motivate students, as they can see the practical application of their studies.

Furthermore, educating students about the importance of safety and environmental considerations in process engineering is crucial. As future engineers, they must be well-versed in the regulations and ethical standards that govern the industry. This education should encompass topics such as hazard analysis, risk assessment, and sustainable practices. The goal is to instill a sense of responsibility in students, encouraging them to prioritize safety and sustainability in their work.

Another key aspect of process engineering education is fostering critical thinking and problem-solving skills. Students should be encouraged to approach engineering problems systematically, utilizing analytical tools and methodologies. Problem-based learning strategies can be particularly effective in this regard, as they challenge students to think creatively and develop innovative solutions to complex issues.

Assessment methods also play a significant role in process engineering education. Traditional exams may not effectively measure a student’s understanding or ability to apply knowledge. Instead, a combination of project work, presentations, group discussions, and reflective practice can provide a more comprehensive assessment of a student's capabilities. This approach not only evaluates their technical skills but also their ability to communicate and collaborate effectively.

In conclusion, enhancing Process Engineering Education requires a holistic approach that integrates theory with practice, leverages technology, fosters industry partnerships, emphasizes safety and sustainability, and develops critical thinking skills. By focusing on these areas, educators can better prepare students for the challenges they will face in their careers, ensuring that the next generation of process engineers is equipped with the knowledge and skills necessary to succeed.